What do Marine Exhaust Manifolds refer to?

Marine propulsion systems are incredibly complex units that have to function efficiently and smoothly without fail. Unlike car engines that can take some wear and tear, along with occasional breakdowns, marine engines must keep performing without any issue.

It cannot afford to a breakdown in the middle of a voyage, since the nearest source of aid might be thousands of kilometres (technically, nautical miles) away. Thus, to keep the propulsion systems functioning effectively, a combination of sub-systems and integral machine parts are required to work in a synchronized manner.

Should even one component give out, the entire engine might face catastrophic failure that could have far-reaching consequences on the safety of crew members and passengers.

One highly probable reason for an engine to malfunction could be the buildup of fumes within the system. These fumes are generated during the normal functioning of the engine when fuel is ignited within the engine cylinders.

Marine Exhaust Manifold plays a crucial role in keeping the engine system functioning at peak performance.

In this article, we will look at the working, construction, and structure of marine exhaust manifolds. We will also analyze how the manifold systems differ between ships and smaller vessels such as yachts and boats.

Lastly, we will look at some of the common problems and repairs that may be encountered while working with exhaust manifolds.

Function and Parts of an Exhaust Manifold

The exhaust manifold is an important part of any propulsion system. It collects the exhaust fumes generated from the engine during combustion of fuel and redirects it into the exhaust pipe. From the exhaust pipe, the gases are released into the atmosphere after treating it for poisonous and toxic particles.

Noise levels within the entire propulsion system can be very high. These generally exceed the acceptable industrial levels and may lead to hearing-related impairments for operators.

Noise reduction is achieved using a muffler located within the exhaust pipes. We can see that several components come together to form the entire exhaust system.

This system is required to ensure proper handling of the exhaust gases and fumes. Once generated by the engines, gases and fumes need to be whisked away into the main exhaust system. In case this does not happen, the gases may build up within the engine itself, or may even leak into living quarters and other areas of the ship.

In the case of small boats and yachts that use outboard motors with faulty manifolds, there is a high probability of asphyxiation due to the building of noxious fumes. In case of gas build-up within areas of the engine, it may lead to spontaneous combustion due to prolonged exposure to high working temperatures.

In such a confined environment, an explosion could well capsize the ship by rupturing the hull region near the aft.

The manifold consists of three main parts-

- the connection flanges,

- primary tubes, and

- the manifold body.

- Small boats also have a manifold casing.

The connection flanges refer to the structure between the engine and the exhaust system that keeps both connected. It is fitted snugly into place using manifold bolts and fasteners. In addition, a heavy-duty gasket is also fitted around the flange, such that gases can be contained within the system.

Due to the near-constant high-temperature conditions, these flanges receive enormous stresses and must be cooled appropriately at regular intervals. Also, they receive large vibrational shocks during engine operations and have to be suitably reinforced to handle the forces.

Primary tubes are connected to the flanges and carry the gases up to the main body of the manifold. They are provided with a basic cooling system intended to rapidly reduce the temperature of the gases within the tubes. In most cases, the cooling system is made up of a recirculating water jacket that siphons away heat from the tubes.

Other types of coolants are available commercially, but water is commonly used due to the easy availability during a journey. Such a structure with external circulating coolant is known as a dual-pipe design (since the internal pipe holds gases, and the external pipe contains the coolants).

The manifold body is the main structure that we refer to when speaking of the exhaust manifold. It serves as a collection point for all the engine gases and fumes. From there, they are carried through the marine exhaust riser into the main exhaust pipe for further processing. The manifold is cooled in a manner similar to the primary tubes.

In general, most parts of the exhaust system use the dual tube arrangement, with a secondary cooling jacket covering the main tube or body. Coolants or chilled air are circulated within this cavity.

Lastly, the manifold casing is found onboard boats and yachts, to prevent accidental contact with the super-heated surface of the manifold. It is built of a durable thermoset material that can absorb large amounts of heat without suffering major structural changes.

To access the internal machinery, this unit has to be unbolted and removed. It is generally connected to the upper portion of the outboard engine at the aft of small vessels.

How is the Manifold Different on Boats and Ships?

The manifold system differs between large ships and smaller boats. This is because the system copes with different types of gases and operating environments.

Onboard ships, the manifold system is built to be robust and capable of withstanding large temperatures and stresses. It is generally constructed of an alloy of steel or similar metal such that it retains strength even during harsh operating conditions.

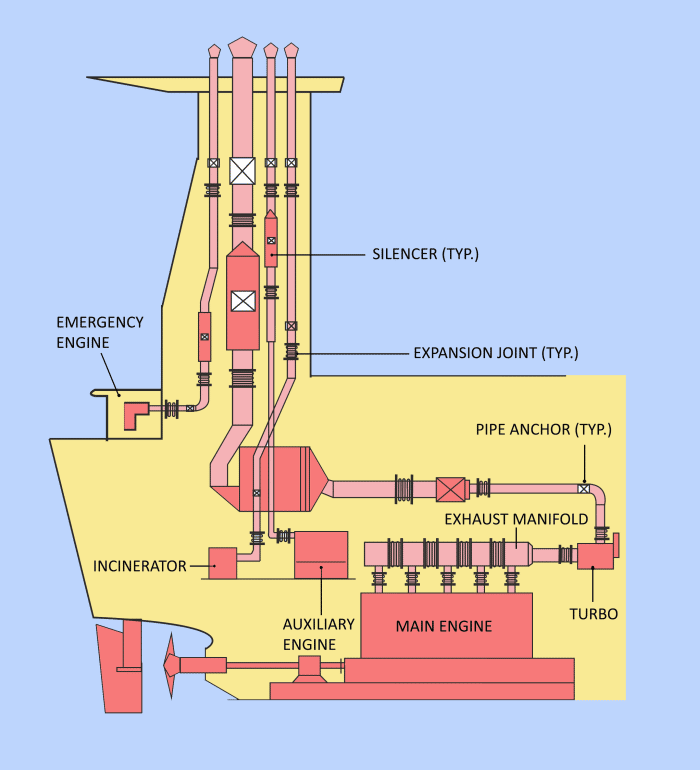

It is bolted to the top of the engines and rises upwards from the engine room. In addition, it primarily discharges fumes and gases into the atmosphere after treating for toxic by-products.

On the other hand, boats use smaller systems that are easy to install and repair. They come with a manifold casing, and the entire unit sits on top of the engine. The exhaust pipe does not rise upwards and instead discharge fumes near the waterline.

Care must be taken to ensure that there is no backflow or accumulation of water within the exhaust system. Additionally, some designs mix the engine gases with controlled quantities of water such that it may be safely discharged into the ocean or sea.

The manifold systems on ships do not suffer from the danger of water accumulation within the system. Most of the maintenance requirements arise from regular checks on the condition of the machinery. Taking apart the manifold for inspection is a time-consuming affair, and ship operators prefer to only conduct annual checks unless specifically required.

However, on boats, the manifold can be easily removed, repaired, and refitted without needing a large amount of time.

Problems Faced During Manifold Operation

The manifold is subjected to very high temperatures for extended periods of time. In addition, it also faces large vibrational forces and shocks caused due to the operating environment of the engine. These forces and temperature changes are detrimental to the working life of any engine component. Also, there are several other issues that commonly crop up within the manifold during engine operation.

In this section, we will look at the major problems that may arise in the manifold while operating a vessel.

Primarily, temperature gradients can vary drastically within the operating environment in the engine area. During sailing, the temperatures soar up due to the combustion process and subsequent gas build-up, often reaching hundreds of degrees centigrade.

At the other extreme, while berthed at docks and yards, the ship’s engine systems are at a dead halt with almost no working component. In such situations, the engine component temperatures drop down to ambient levels.

Repetitive cooling and heating cycles can lead to structural deformities in the exhaust manifolds. As the manifold is in direct contact with the main engine parts, it faces more drastic temperature changes as compared to other components. Since it is built as a rigid part that is not intended to be flexible, it has a high tendency to crack and deform under these intense conditions.

Next, vibrational shocks are to be accounted for in all engine-related components. The large RPMs at which the engine pistons operate create secondary oscillations in other parts. These can create temporal damages (time-based) due to rapid flexure of rigid metal parts. In addition, forces also act on the manifold that can lead to structural damage. The worst possible scenario is in case the natural frequency of the manifold matches the operating frequency of the engine. This results in large amplitude oscillations that will lead to permanent damage to the manifold and other surrounding components.

Image Credit – Deven Aranha

Next, the accumulation of various substances within the manifold has far-reaching consequences on the long-term performance of the entire engine system. Common exhaust manifold pollutants include salt and carbon-based deposits. Salt is accumulated within the manifold during operations when seawater is used for cooling the system. Another reason for accumulation could be when water enters the system due to a leak or crack in the external casing.

The deposition of salt on the interior is known as scaling, and it severely affects the performance of the vessel. By clogging the pipes, it decreases the diameter through which gases vent, which can lead to increased backpressure. This decreases the overall efficiency of the engines.

Beyond a certain limit of back-pressure, the engine pistons might be permanently deformed owing to the enormous pressure. On the other hand, deposition of carbon-based pollutants can lead to environmental regulation violations. By having deposits along the pipe surface, the high concentrations lead to large quantities of unburnt hydrocarbons and soot being released into the ocean without filtering. This can cause major changes to existing marine flora and fauna.

There are strict regulations in place to ensure proper handling of the exhaust system, such that there are no harmful pollutants deposited into the ocean or sea.

Lastly, the effect of water gaining entry into the manifold system can be very dangerous during operations. The manifold is built in such a manner that the exhaust gases are cooled prior to either being released or being reused by the turbo.

Cooling is carried out by encasing the primary manifold and exhaust pipes with a surrounding water jacket. This lowers the temperature suitably before the gases are released. In cases where the exhaust gases are vented directly into the air through a vertical pipe, the gases never come into contact with the coolant or other fluids. However, there are some designs that mix the coolant with the gas and discharge them back into the water. In such cases, the mixing process is critical.

Ideally, the mixing occurs much after the manifold such that there can be no backflow. However, in case of any cracks or leaks in the exhaust pipes, water may flow into the manifold and surrounding region. This results in corrosion and severely affects the life of the system. During vessel motions, water may even enter the engine pistons.

When started, the pistons will suffer a catastrophic failure and near irreparable damage due to the presence of water inside the cylinder. Water is not compressible as compared to gas, and can rupture the piston cylinders during operation. This may require replacing the entire exhaust and engine system, which is considerably expensive. Thus, care must be taken to prevent water from entering the exhaust systems.

How to Maintain and Repair Exhaust Manifolds

Since the exhaust manifold serves as the main entry point to the remainder of the exhaust system, it must always be in working order. Any problems- minor or not, can have serious consequences on the performance of the vessel.

While on small boats and yachts, the manifold can always be disassembled and cleaned in case of an issue, large ships weighing hundreds of thousands of tons cannot afford that luxury. For such ships, the manifold is located deep inside the hull of the ship. The only time it is opened up and cleaned is during the annual maintenance or in case of emergencies.

Thus, maintenance plays a major role in keeping the entire ship functioning efficiently. Although the highest standards of maritime construction are followed, problems do occasionally occur. The exhaust manifold serves as the chokepoint between the engines and the rest of the exhaust system. Any problems will be reflected on all other components and can have serious consequences on the vessel. Maintaining the exhaust manifold involves different procedures for ships and smaller boats.

For ships, the exhaust manifold can be accessed from the engine room located inside the hull. This room also houses the marine diesel engines and houses the initial portion of the marine propeller shaft. The manifolds are connected at the upper portion of the engine such that exhaust fumes are pumped out and redirected. Prior to any repair, the entire propulsion system must be shut down and given sufficient time to cool down.

This is because the high temperatures within the engine can lead to damage to other components and injure the operator. To keep the manifold in position during the high RPM functioning, heavy-duty bolts and fasteners are used to secure the connection. These bolts require frequent checks and replacement since they suffer from very high stresses due to the constant vibrational force.

Inside, the surfaces often need to be sanded, ground down, or cast again depending on the condition of the manifold. In case of any deposition on the interior surface, the deposits need to be ground away. After this, a new coat of anti-rust and other chemical agents are applied.

However, there may be occasional dents or other damages that extend deep inside the metal casing of the manifold. These could be due to external shock or corrosion within the manifold. In such situations, that particular region of the manifold is cut out, and then recast to fill the gap. Repeated recasting is inadvisable, as the process exerts large stresses on the rigid manifold casing.

For this reason, the manifold is often built from smaller sections that can be taken apart easily. Thus, only a certain section needs to be replaced as opposed to recasting the affected region.

For boats and trawlers, the manifold can be easily accessed, since it is often mounted on the top of the outboard motor. Here, the danger of water entering the exhaust system is considerably higher, since it vents gases near the water level. Thus, appropriate measures have to be taken to ensure that the exhaust vent remains safely above the waterline at all times. In the case of exhaust systems based on the mixing of coolant and exhaust fumes, the released fluid must be monitored for temperature and particulate matter. These are early warning signs of any major leakage inside the engine and manifold.

In all types of vessels, it is prudent to have temperature gauge connected to the marine exhaust manifold, and the exhaust pipe. This allows the crew to monitor the exhaust system for any possible problems since temperature changes of the working components signal an issue within the propulsion system.

Overall, it is important to observe the exhaust system for any tell-tale signs of trouble.

Regular maintenance and care taken during operation can go a long way in prolonging the life of the entire engine system.

Comments

Post a Comment