#40 Starting Procedure for Turbine Generator on Ship

With its fixed and moving cutting edges and alternators, the steam turbine is a heat engine that converts high temperature and high strain steam intensity energy to mechanical or electrical energy. The steam turbine serves a number of functions and is an ideal core player. In power plants, larger steam turbines are used to power generators, and smaller steam turbines can be used to power siphons and fans. The power range of steam turbines is 0.5 to 200,000 HP.

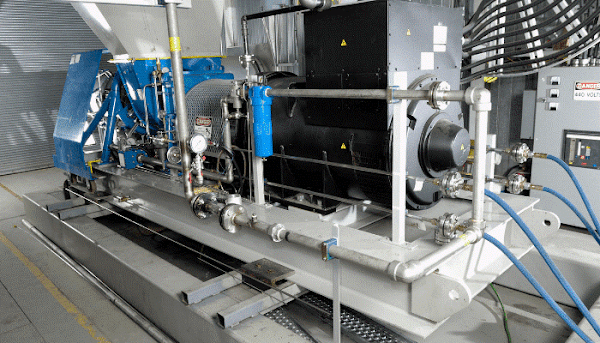

In order to prevent the smooth operation of the entire system, the ship's turbine generator has suitable standard operating procedures under sequential starting and shutting down procedures. The right technique makes sure that no equipment component experiences any form of stress, whether thermal or mechanical. Additionally, it ensures that no additional time is wasted as the ship operates.

Following are the proper procedures for the ship's steam turbine generator:

Pre-starting procedures

- All bearing points should have their lubrication closely monitored.

- All water cooling systems should have flowing cooling water.

- Check the major mover power (or steam, etc., as the primary impulse).

- Manually rotate the pump rotor.

- You should check the fluid level at the draw side.

- If the conveyance valve for the centrifugal pump is closed, it should be open

- The siphon should be gradually warmed by idly circulating hot fluid through the siphon.

- The sidestep or spill-back line needs to be open.

Starting Procedures

- Check the level of the lubricant oil sump in the turbo generator and drain any water. If the level is lower than usual, replenish it.

- From the nearby station, start the lube oil priming pump, then check the lube oil pressure. the priming pump to automatic.

- Inspect and re-fill the operational water tank for the turbine generator's vacuum pump to the proper level.

- Check the condensate level in the vacuum condenser using the condensate pump. Set the pump to run automatically to ensure that the level is always maintained.

- To lessen excessive hammering and vibration when starting the turbo generator, turn the steam drain valve to discharge any condensed water from the steam line.

- Open the turbo generator's main steam inlet valve.

- Return the gland steam pressure to the desired setting.

- The seawater valves for the vacuum condenser, T/G lube oil cooler, and vacuum pump cooler should be checked and opened.

- Turn on the vacuum pump to increase the condenser's vacuum.

- Turn on the pump and open the valves on the condensate pump.

- Verify that the lubricating oil pressure, gland steam pressure, and condensate vacuum are all within normal ranges.

- Open the drain in the steam pipe and start the turbo generator at the nearby station.

Check the steam pressure in the first and second stages.

- Verify the water level and condenser vacuum.

- Examine the vibration and lubrication oil pressure levels.

- Verify the condenser level, vacuum, voltage, and other characteristics of the turbo generator.

- Transfer control from the local control to the remote station and load the TG.

- Pay close attention to the steam temperature.

- Temperature, pressure, flow, and other factors need to be closely monitored.

- Verify the vibrations and temperature of each bearing point.

- Properly inspect the Condenser vacuum structure.

- Keep the condenser level control framework consistent. • Watch the turbine ejector framework.

- Examine the stuffing box overflow thoroughly.

Shutting down procedure

- Reduce the load incrementally until it is nil.

- Start the auxiliary oil siphon and check to make sure the proper strain is maintained when the turbine is coming to a complete stop.

- Open the emergency valve. The vacuum breaker is also controlled by this valve.

- High pressure should be applied to close the hole; at about one psi, steam is let into the chamber and the water supply is turned off.

- Terminate the collection or cooling of water.

- Turn off the gathering apparatus and let the turbine's packing and funneling channels open.

- Once the turbine rotor has stopped, continue using the auxiliary oil siphon function.

- In the event that the turbine is left idle for a longer period of time to cool to room temperature, the condenser pneumatic pump is utilized to dry it out. As a result, it aids in preventing hardware wear.

Maintenance of Steam Turbines

The production of electricity for both the primary and auxiliary equipment on board ships depends on stream turbines. Thus, maintaining the steam turbine's operation and performance is essential to ensuring high turbine reliability and the efficient running of the ship and other related machinery.

The following are some best practices for operating a steam turbine:

Steam quality– Steam ought to be of the highest caliber. Condensate entanglement in the steam feed raises turbine steam rates, which reduces steam turbine efficiency and leads to steam turbine component disintegration. If the quality of the steam supply is questionable, a mechanical mixing separator should be installed before the turbine delta to prevent condensate- and lower-quality steam-containing condensate from entering the turbine.

Pipe Expansion and Contraction- To ensure that no unnecessary powers are sent to the turbine spines, steam piping needs to be inspected, examined, designed, and properly installed.

Supply and Exhaust Line Sizing- In order to provide full-line steam strain at the turbine gulf at the maximum load, steam piping should be designed. The stockpile line size needs to be calculated for the heap as well as the strain decreases due to the length of the line and other framework components, such as valves and fittings.

Steam Piping Supports- All steam funneling requires assistance due to the additional line weight. The two types of assistance that are typically used practically are rigid plans and spring plans. The two types are meant to aid in funneling, but not in directing the line for developmental purposes. However, when an extension joint is present, a rigid support can be used to restrict the growth of channeling. Ordinary buildings use guides, supports, and anchors..

Precautions

Before beginning the turbine, the operator must become familiar with the general channeling design, the working characteristics of the unit, and the manufacturer's operating instructions. • The steam should be superheated or supersaturated before reaching the turbine. Inadequate knowledge may lead to tragic accidents.It should be noted that a large turbine has restricted clearances, making extension or improper handling more dangerous than with a small one.

Comments

Post a Comment